Beam Shaping: Techniques and Applications for Enhanced Precision

Beam shaping might sound like a technical term reserved for scientists and engineers, but its implications ripple through various industries. Imagine the difference between a focused laser beam slicing through metal with precision versus a wide dispersive beam that lacks control. That’s where beam shaping steps in—transforming raw energy into precisely controlled outputs.

This technology is not just about improving performance; it’s about unlocking new possibilities across fields from manufacturing to medicine. As we delve deeper into the world of beam shaping, you’ll discover innovative techniques, fascinating applications, and real-world success stories that illustrate its impact. Whether you’re an industry professional or simply curious about advancements in technology, understanding beam shaping can enhance your perspective on how light and energy influence our lives every day.

Types of Beam Shaping Techniques

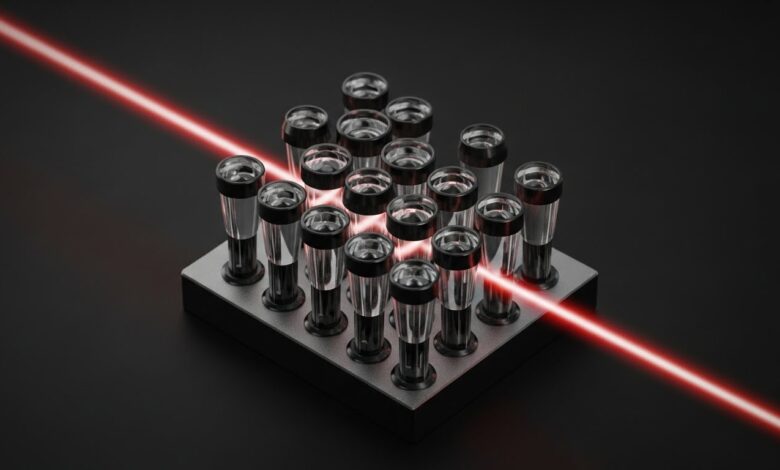

Beam shaping techniques come in various forms, each tailored to meet specific needs. One common method is the use of optical elements such as lenses and mirrors. These tools manipulate light paths to create desired beam profiles.

Another technique involves diffractive optics. This approach uses microstructures etched onto a surface to control how light disperses. It enables precise alterations in beam shape for applications ranging from telecommunications to laser cutting.

A third option is spatial light modulators (SLMs). By dynamically changing the phase or amplitude of incoming beams, SLMs allow real-time adjustments that can enhance focus and intensity distribution.

There’s also wavefront shaping, which employs adaptive optics systems. These systems correct distortions in light waves, improving clarity and precision in imaging tasks like astronomy or microscopy.

Each technique possesses unique strengths, making them suitable for different scenarios across industries.

Applications of Beam Shaping in Different Industries

Beam shaping has found a place in diverse industries, transforming how processes are conducted. In manufacturing, laser beam shaping enhances cutting and welding precision. This ensures cleaner edges and reduces material waste.

In healthcare, beam shaping plays a pivotal role in medical imaging techniques like MRI and CT scans. Optimized beams improve image quality, leading to better diagnoses.

The entertainment sector also benefits significantly from this technology. Laser shows utilize precisely shaped beams to create stunning visual effects that captivate audiences during concerts and events.

Moreover, telecommunications leverage beam shaping for fiber optics. By manipulating light paths, data transmission becomes more efficient over longer distances.

Agriculture isn’t left out either; precision farming uses shaped laser beams for targeted treatments of crops. This innovation minimizes chemical usage while maximizing yield potential.

Advantages and Disadvantages of Beam Shaping

Beam shaping offers several advantages that can greatly enhance various processes. One key benefit is the improvement in precision. With tailored beam profiles, applications such as laser cutting and medical procedures see significant enhancements in accuracy.

Additionally, optimized energy distribution allows for more efficient use of resources. This not only reduces waste but also lowers operational costs over time.

However, beam shaping isn’t without its drawbacks. The initial setup can be complex and may require sophisticated equipment or software adjustments. This complexity might deter smaller operations from adopting these techniques.

Moreover, there’s a potential learning curve involved for personnel who must adapt to new systems and technologies. Training costs can add up quickly, making it an important consideration for businesses weighing their options in beam shaping implementation.

Case Studies: Success Stories of Beam Shaping Implementation

One compelling example of beam shaping can be found in the field of laser surgery. A medical facility adopted advanced beam-shaping techniques to enhance precision during delicate procedures. The result? Reduced recovery times and improved patient outcomes.

In manufacturing, a leading aerospace company utilized customized beam profiles for cutting materials. This innovation allowed them to achieve intricate designs with minimal waste, boosting both efficiency and quality.

Another fascinating case emerged from telecommunications, where optimized optical beams dramatically improved signal transmission over long distances. By fine-tuning light patterns, engineers reduced interference and enhanced data rates significantly.

These success stories highlight how diverse industries are leveraging beam-shaping technologies to overcome challenges. Each implementation not only demonstrates technical prowess but also showcases the transformative impact on operational effectiveness.

Future Developments and Potential Impact on Various Fields

The future of beam shaping holds remarkable promise across numerous fields. With advancements in materials science and optical engineering, we can expect more precise control over light distribution.

Innovations like meta-surfaces are paving the way for compact devices capable of complex beam profiles. These changes could revolutionize applications in telecommunications, making data transmission faster and more efficient.

In the medical field, enhanced beam shaping techniques may lead to breakthroughs in laser surgery. Improved precision can minimize damage to surrounding tissues while maximizing treatment effectiveness.

Moreover, industries focused on renewable energy might benefit from optimized solar concentrators that increase energy capture significantly. This shift can contribute substantially to sustainable practices worldwide.

As research progresses, interdisciplinary collaborations will unlock new avenues for exploration. The integration of artificial intelligence with beam shaping technologies is likely to yield even greater improvements in performance and application versatility.

Conclusion

The world of beam shaping is evolving rapidly, offering innovative solutions across various fields. As industries continue to seek greater precision and efficiency, the techniques and applications of beam shaping will undoubtedly play a pivotal role in advancing technology.

With an array of methods available—from optical filters to diffractive elements—organizations can tailor their approaches based on specific needs. The versatility of these techniques makes them applicable in healthcare, manufacturing, telecommunications, and beyond.

While there are notable advantages like improved performance and enhanced control over light propagation, it’s essential also to consider potential drawbacks such as increased complexity or cost implications. Nevertheless, successful case studies demonstrate that when effectively implemented, the benefits often outweigh the challenges.

As research progresses and technologies are refined, we can anticipate even more groundbreaking advancements in beam shaping. These developments could transform not just industrial practices but also consumer experiences in everyday life.

Embracing beam shaping today could be key for businesses aiming to stay ahead in tomorrow’s competitive landscape. The impact is undeniable; it’s an exciting time for both researchers and practitioners involved in this dynamic field.